Lithium Battery Defect Detection Equipment

Equipment Overview:

●online high-speed detection, improve detection efficiency and accuracy, reduce labor costs.

●high pixel industrial camera precise identification, the number of cameras on demand design, accuracy0.1mm, the detection speed can be customized according to the detection requirements.

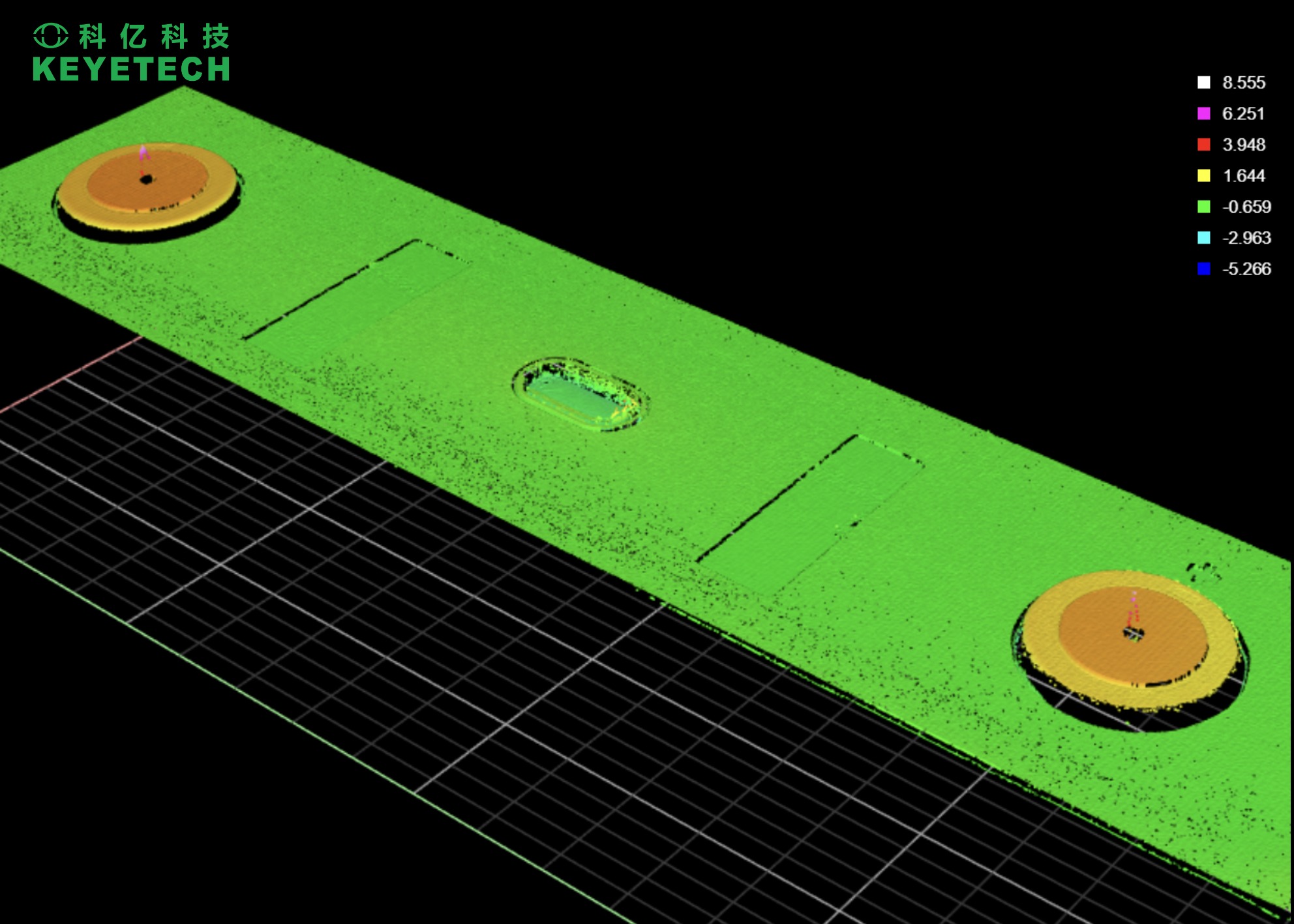

●inspection category: coating, slitting, die-cutting, winding, cutting and stacking, hot pressing, matching inspection, packagingMylar film, shell entry, tab welding, cover plate welding, coating, module appearance, etc.

●detection range (take coating and module appearance as an example):

●coating: width of coating area, width of non-coating area, dislocation size of front and back, scratch of coating area, fold of pole piece, fold of blank area, particle bulge, bubble, dry crack, stripe color difference, wavy pattern, drum edge, copper leakage, sticking material, coating scratch, etc.

●module appearance: smooth weld without potholes, broken welding, bursting points, black spots, dirt, pinholes, weld deviation, too narrow weld, poor welding, etc.

Product Configuration:

●high pixel industrial camera

●High Resolution Industrial Lenses

●high brightness stroboscopic light source

●with independent intellectual property rightsartificial intelligence (Al) algorithm

●High PerformanceGPUcomputing processing platform

●high resolution industrial touch screen

●double culling system to prevent missed kick, and can partially achieve classification culling