Machine Vision in Straw

people, and the catering industry is China's livelihood industry,and straws, like chopsticks and spoons, are important dietary tools in people's lives., especially when drinking juice and carbonated drinks, more and more people are inclined to use straws.At this stage, straws on the market are mainly paper straws, plastic straws, degradable straws, silicone straws, etc., each has its own advantages and disadvantages; among them, with the strengthening of environmental governance in the country, the industry share of plastic straws has declined, and straws of other materials have been chosen by more enterprises and individuals.

1

manufacturing process is complex, defects are difficult to avoid

Examples of plastic straws, the whole production process is roughly divided into raw material mixing, extrusion molding, cooling and shaping, etc. After the plastic raw materials are stirred and melted, the plastic is extruded through an extrusion die, and then the machine extrudes the plastic like a syringe. When the plastic is still softened, it is fed into the machine for direct molding, and then the machine is used for cutting in the later period. The processing technology is complicated, which cannot avoid various defects and bring serious hidden dangers to product quality. Manufacturers usually increase the manual way to control product quality. Butmanual detection efficiency is low, the cost is high, and the manpower is limited, extremely unstable factors. With the construction of automated factories and the development of intelligent modern society,, more and more enterprises have gradually used machine vision to replace manual quality inspection.

2

Major Defects

1.Appearance dimension inspection(including long and short term dimensions, width, etc.)

2.envelope(film edge size, film damage, poor sealing, burning, fried bag, empty bag, etc.)

3.Pipe surface appearance inspection(appearance stains, scratches, different colors, hole damage, etc.)

4.Pipe shape detection(whether it is reversed, deformed, flattened, cut angle, etc.)

5.foreign matter detection(raw material scraps, hair, mosquitoes, etc.)

3

Keyi Technology Visual Inspection Working Principle

"machine vision" is the use of machines instead of the human eye to make a variety of measurements and judgments.Science and Technology integrates optical, mechanical, electrical, computing, soft and other technologies,involves artificial intelligence, computer science, image processing, pattern recognition and many other fields. The equipment is based on the lighting imaging system, through the acquisition of product images, transmitted to the dedicated image processing system, according to the pixel distribution, color and other information into digital signals,analyzes and processes the image, extracts the characteristics of the target, and controls the operation of the device according to the result of the discrimination.

4

technology in straw detection

Keyi Technology has a fully independent research and development platform, covering the full technology chain of "light, machine, electricity, calculation and software". The doctoral team leads the direction and has successively completed equipment delivery with several straw manufacturers, covering many types such as "plastic straws, paper straws, degradable straws" and so on.

1.the independent development of lighting imaging system, according to the defects of different positions, the use of customized imaging scheme, surface light source, combined with customized camera, can achieve the high quality imaging effect of straw.

2.independent research and development of AI algorithm system and small sample defect training, which can adapt to the defect change of straw.

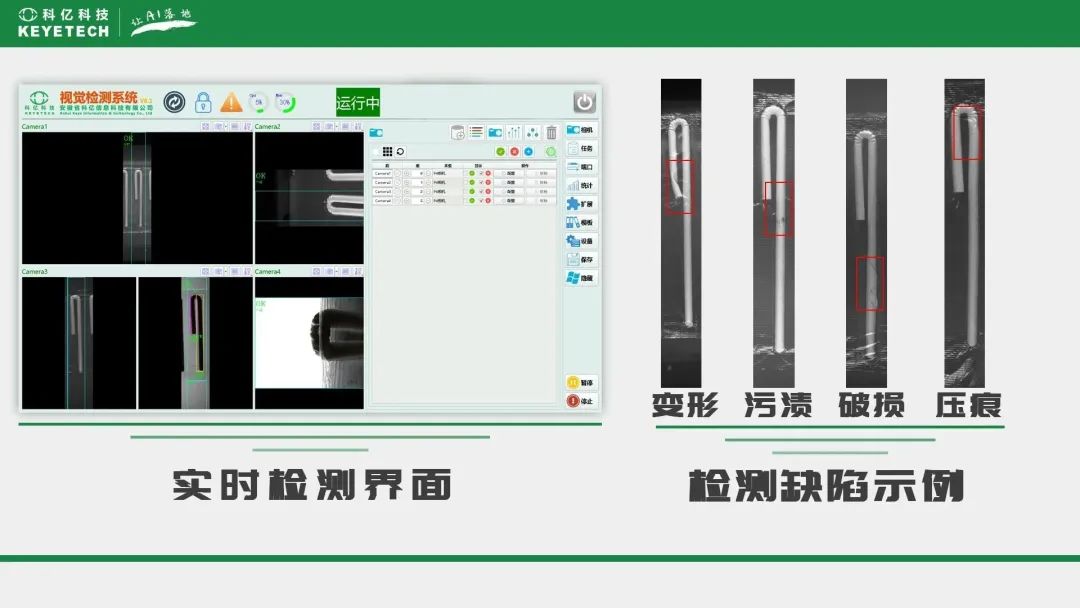

3.human-computer interaction software system, graphical interface, real-time display of straw dynamic images, data statistics, master real-time production status.

4.One-stop visual inspection scheme, the speed can reach 1200/min, the accuracy is 99.8, and the cost is low, which fundamentally solves the problem of cost reduction and efficiency increase of customers.

5.unified testing standards, factory quality control. One investment, the enterprise benefit visible growth.