visual inspection of dry goods! AI Image Visual Inspection Based on Deep Learning Algorithm

KEYETECH

Modern computer vision techniques based on artificial intelligence and deep learning methods have made significant progress in the past 10 years. Nowadays, it is widely used in image classification, face recognition, recognition of objects in images, etc.

So what is deep learning and how is deep learning applied to visual inspection?

1

Part. 1

What is Deep Learning?

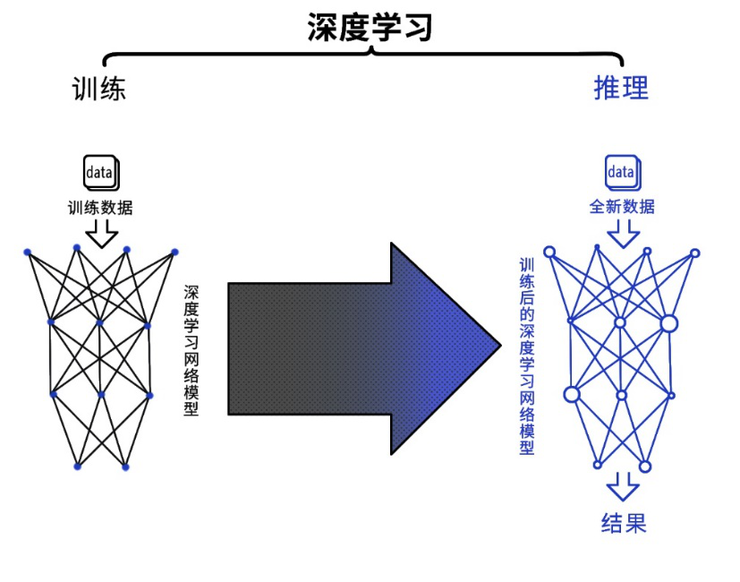

deep learning is a branch of machine learning technology, which consists of artificial neural networks to form a classification recognizer. It works by teaching the machine to learn by example, providing the neural network with labeled examples of specific types of data, and then extracting common patterns between these examples and transforming them into a neural network model that contains this information, which helps to classify the information obtained in the future.

visual inspection based on deep learning technology,can achieve positioning, distinguish defects, character recognition, etc., during operation,realize the simulation of human visual detection effect.

what does that mean? for example.

wants to create visual inspection software for lithium battery inspection, we need to develop an algorithm based on deep learning,and train it with examples of defects that must be detected. With the defect data, the neural network will eventually detect the defect without any additional instructions.

deep learning-based vision inspection systems are good at detecting defects of a complex nature. They can not only solve complex surface and appearance defects, but also generalize and conceptualize the surface of lithium batteries.

deep learning-based vision inspection systems are good at detecting defects of a complex nature. They can not only solve complex surface and appearance defects, but also generalize and conceptualize the surface of lithium batteries.

2

Part. 2

Convolutional Neural Network?

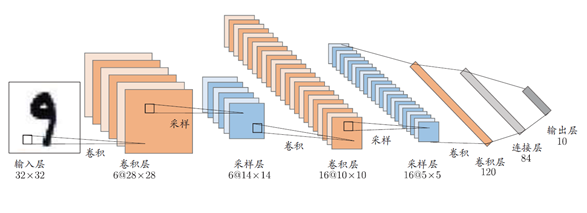

when it comes to visual detection based on deep learning, the most common thing on the market is convolutional neural network, so what is convolutional neural network?

convolutional neural network, namely CNN, has its special function, which retains spatial information in the network, so it can be better applied to image classification problems. The principle is inspired by the data of human visual biology. Vision is based on multiple cortical layers, and each layer recognizes more and more structural information. What we see is a lot of individual pixels; then from these pixels, we identify the geometric components; and then... so that more and more complex elements such as objects, faces, human torsos, animals, etc. are identified.

The use of AI image visual inspection by Keyi Technology.convolutional neural networks, more focused on network cascading,design different network cascading methods for different scenarios to reflect image features more accurately,makes visual inspection more accurate.

3

Part. 3

integrate AI vision inspection systems?

01 Clear Requirements

typically integrates an AI vision inspection system that starts with business and technical analysis. First of all, it should be clear what kind of defects the system should detect and in what environment?

important issues that need to be identified in advance include:

AI detection be real-time or delayed?

AI vision inspection thoroughly detect defects, and should it be distinguished by type?

have any existing software that can integrate vision inspection capabilities, or does it need to be developed from scratch?

system notify the user of detected defects?

AI vision inspection systems record defect detection statistics?

key question is: Is there data for deep learning model development, including images of "good" and "bad" products and different types of defects?

02 Collect and prepare data

Before a deep learning model can be developed, data needs to be collected and prepared. After more than ten years of continuous development and optimization, Keyi Technology has a powerful and rich algorithm library, when faced with new product detection, can be retrieved according to the algorithm library, carried out.incremental/inherited learning, I .e., on the original training resultsAdd a small number of samples, great.reduces training time for new products, to achieve rapid learning.

03 Training and Assessment

the additional samples are collected, the next step is to train them, validate and evaluate the performance of the model and the accuracy of the results.

04 Deployment and Improvement

When deploying a visual inspection model, it is important to consider how the software and hardware system architecture corresponds to the model capacity.

4

Part. 4

AI vision inspection system

packaging container: suitable for product quality control, used to detect product appearance defects, such as black spots, flash, gap, mold number, etc.

Lithium battery: Pinholes, sand holes, scratches, bumps, partial welding and other defects often occur in sealing nail welding and top cover welding in lithium battery production.