-

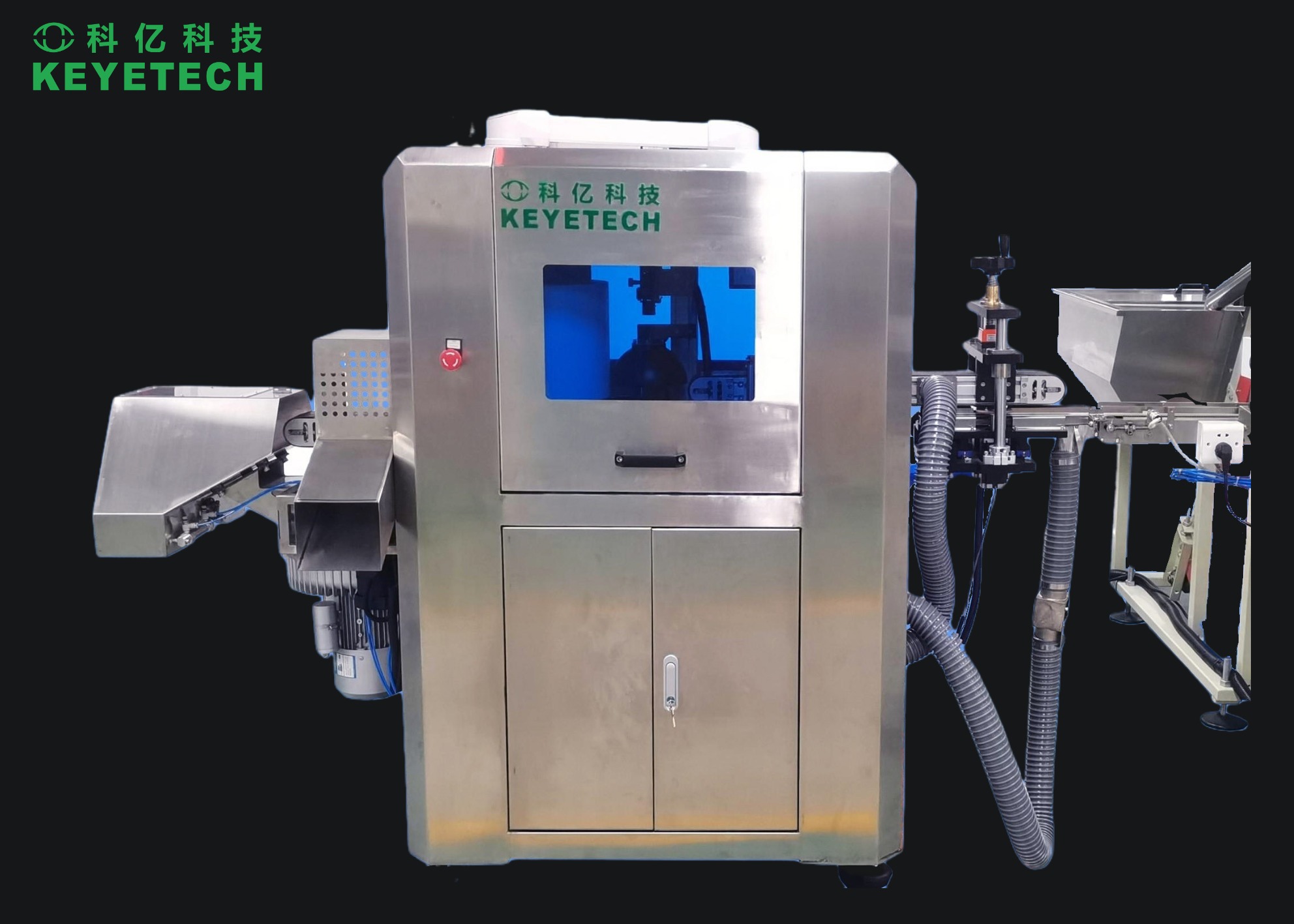

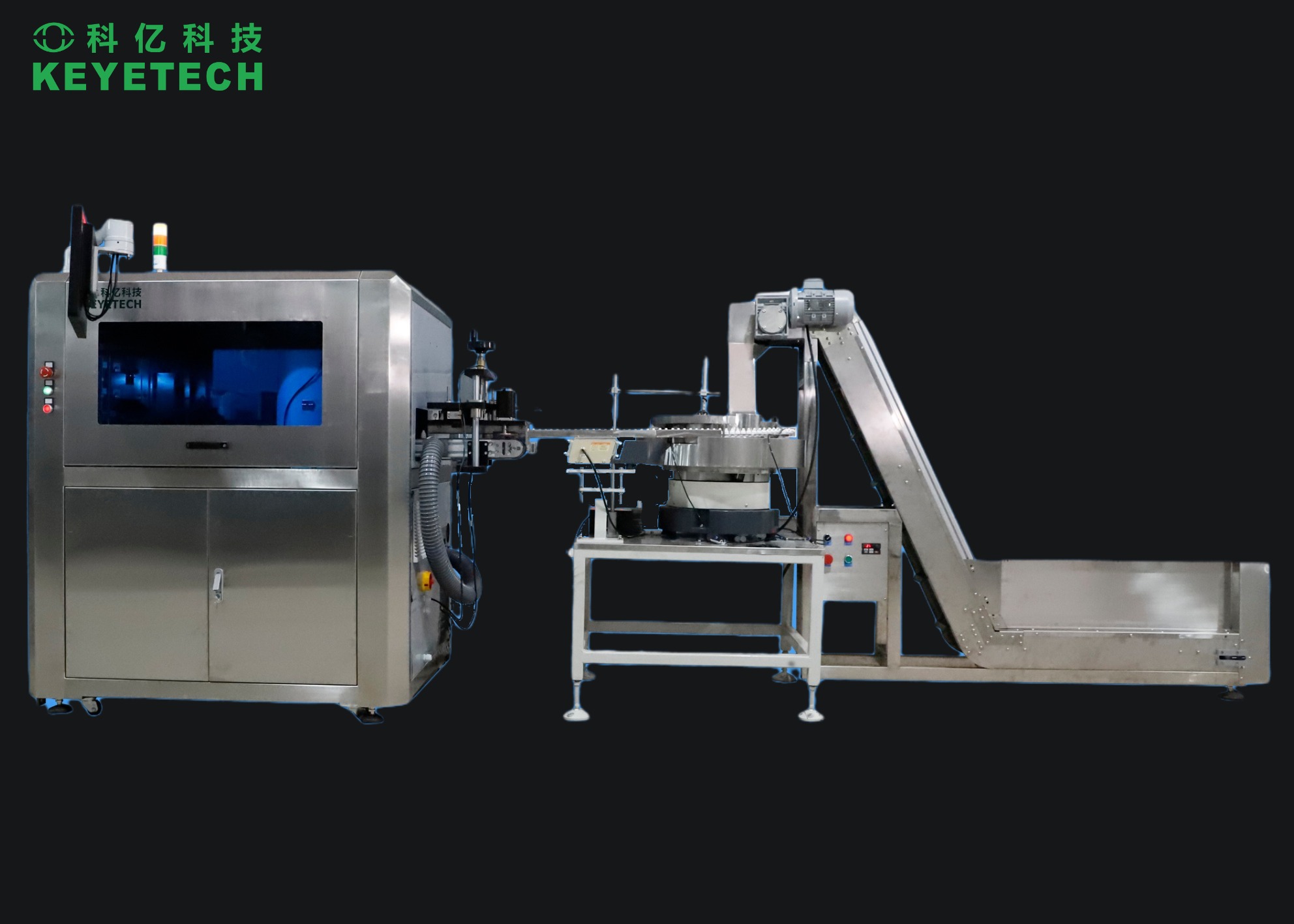

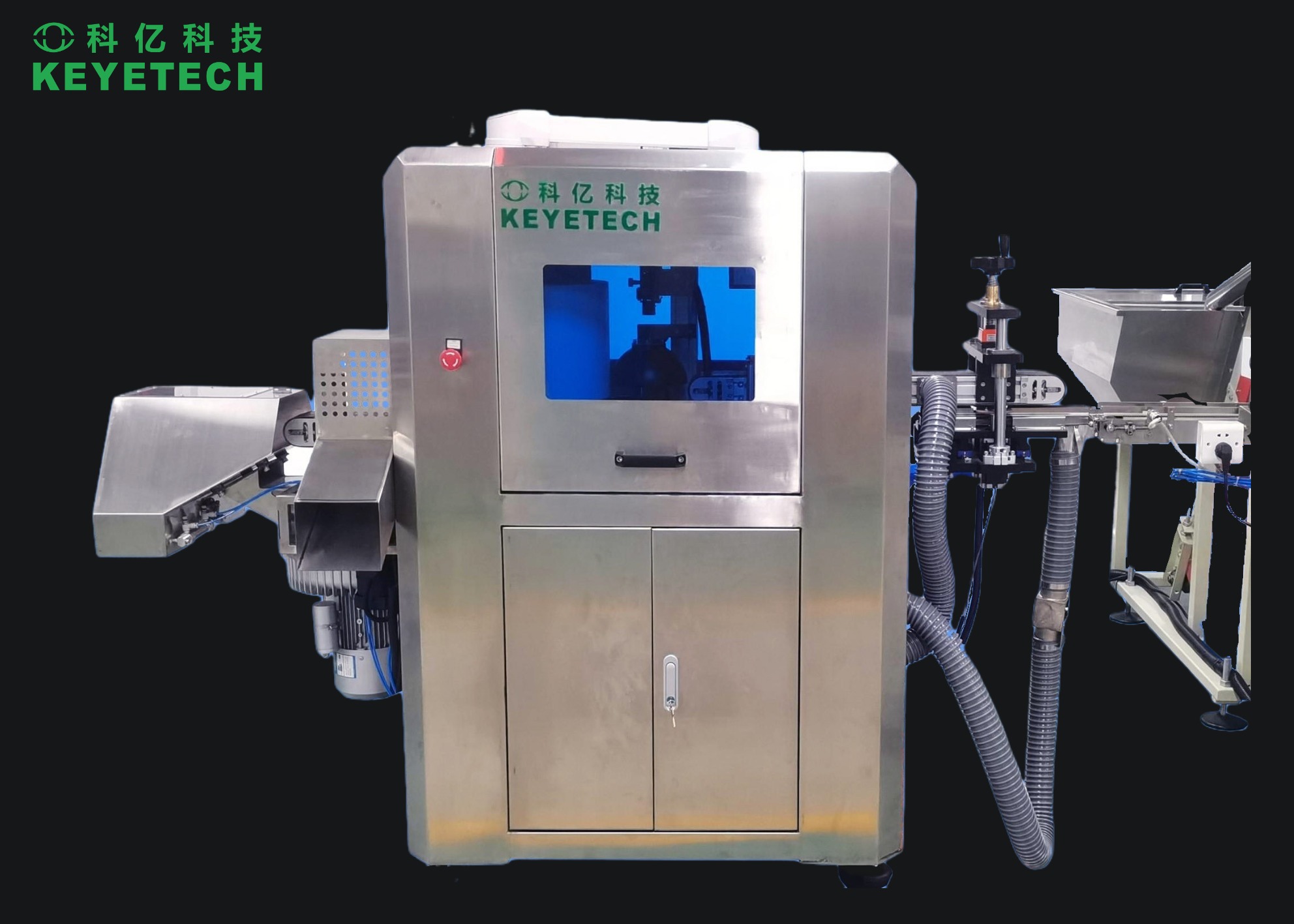

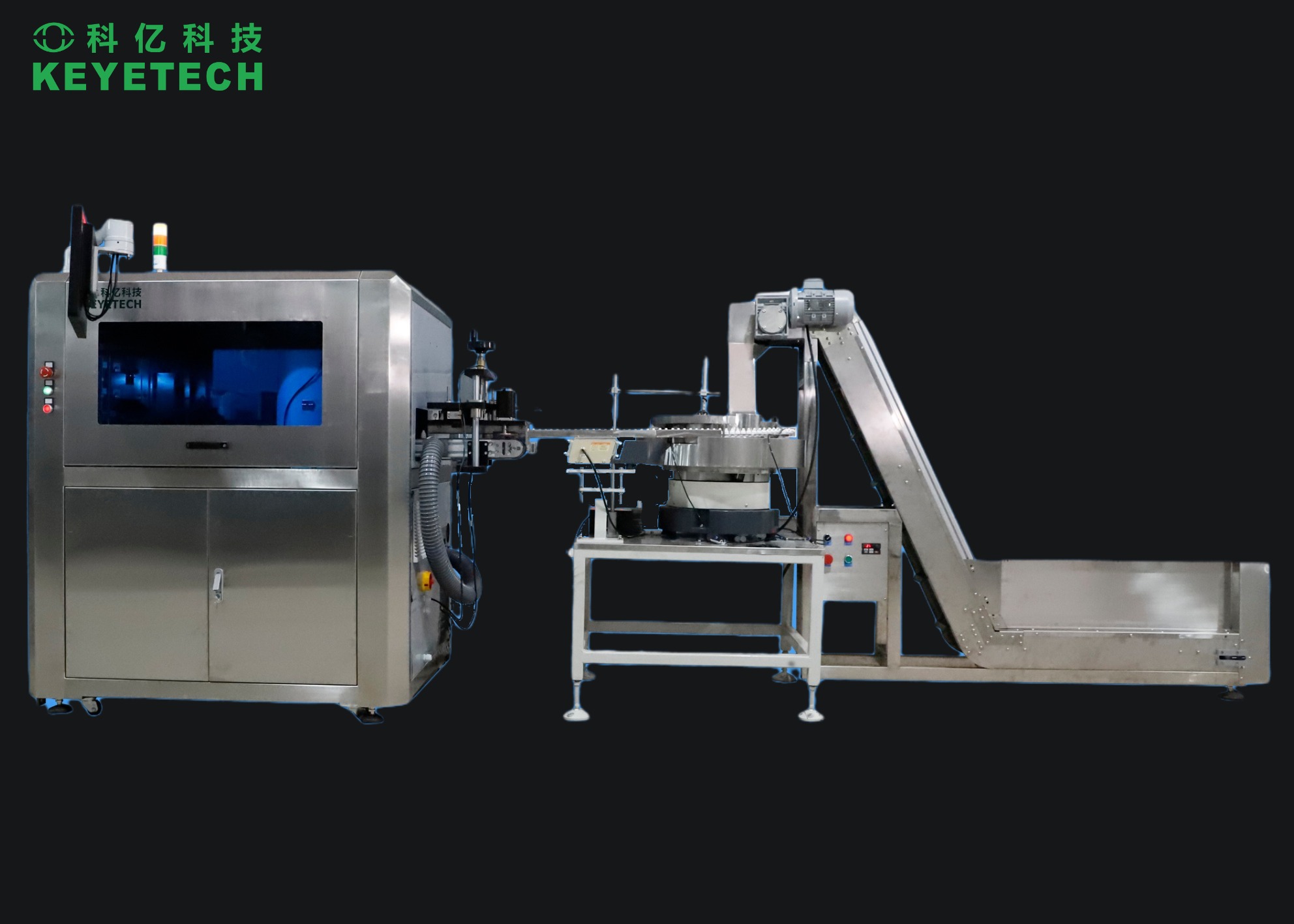

smart cover detection equipment

detection principle:

Through the docking front-end automatic mechanism (which can directly dock various material management mechanisms such as conveying line, waterfall cover management machine, centrifugal turntable, etc., according to the implementation mode to be determined on the production site), the smart cover is stably and orderly transferred to a specific detection station, and then the high-pixel sample image taken is transferred to the image processing software through the industrial2022-02-23 -

High-speed bottle cap defect detection equipment

detection principle

Through the docking front-end automatic mechanism (which can be directly connected to various material management mechanisms such as conveying lines and waterfall capping machines, specifically according to the implementation mode to be determined at the production site), the bottle caps are transmitted to a specific detection station in a high-speed, stable and orderly manner, and then the high-pixel sample images taken are transmitted to the image processing software throug2022-02-23 -

Butterfly cover detection equipment

detection principle

Through the docking front-end automatic mechanism (which can directly dock the conveying line, waterfall cover machine, vibrating plate and other material management mechanisms, specifically according to the implementation mode to be determined on the production site), the butterfly cover is stably and orderly transferred to a specific detection station, and then the high-pixel sample image taken is transferred to the image processing software through the industrial camera, a2022-02-23 -

Wine cover detection equipment

detection principle

By docking the outlet of the front-end wine cover assembly machine, the assembled wine cover is stably and orderly transmitted to a specific detection station, then the captured high-pixel sample image is transmitted to the image processing software through the industrial camera, the good and bad products are detected and determined by AI artificial intelligence algorithm, and the corresponding pneumatic components are controlled to reject the bad products, and finally the qu2022-02-23 -

milk powder cover detection equipment

detection principle

The milk powder cover is stably and orderly transmitted to a specific detection station through the docking front-end automatic conveying line, then the captured high-pixel sample image is transmitted to the image processing software through the industrial camera, the good and bad products are detected and determined by AI artificial intelligence algorithm, and the corresponding pneumatic components are controlled to reject the bad products, and finally the qualified products2022-02-23 -

Roof cover inspection equipment

detection principle

The roof cover is stably and orderly transmitted to a specific detection station by docking the front-end automatic mechanism centrifugal turntable and other material handling mechanisms, then the captured high-pixel sample image is transmitted to the image processing software through the industrial camera, the good and bad products are detected and determined by AI artificial intelligence algorithm, and the corresponding pneumatic components are controlled to reject the bad2022-02-23 -

Nozzle cover inspection equipment

detection principle

Through the docking front-end automatic mechanism (which can directly dock the conveying line, vibrating plate and other material handling mechanisms, specifically according to the implementation mode to be determined on the production site), the suction nozzle cover is stably and orderly transferred to a specific detection station, and then the high-pixel sample image taken by the industrial camera is transferred to the image processing software, and the good and bad product2022-02-23 -

Medical Bottle Cap Testing Equipment

detection principle:

Through the docking front-end automatic mechanism (which can directly dock various material management mechanisms such as conveying line, waterfall cover management machine, centrifugal turntable, vibrating plate, etc., according to the implementation mode to be determined in the production site), the medicine cover is stably and orderly transferred to a specific detection station, and then the high-pixel sample image taken is transferred to the image processing software thr2022-02-23 -

combined cover detection equipment

detection principle

Through the docking front-end automatic mechanism (which can directly dock various material management mechanisms such as conveying line, waterfall cover management machine, centrifugal turntable, vibrating plate, etc., according to the implementation mode to be determined in the production site), the combined cover is stably and orderly transferred to a specific detection station, and then the high-pixel sample image taken is transferred to the image processing software thro2022-02-23

Build AI CITY with Artificial Intelligence Internet of Things Technology